Industry Introduction

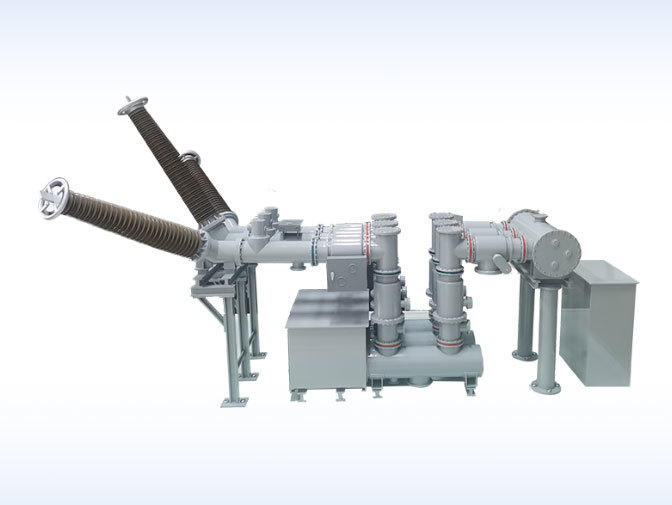

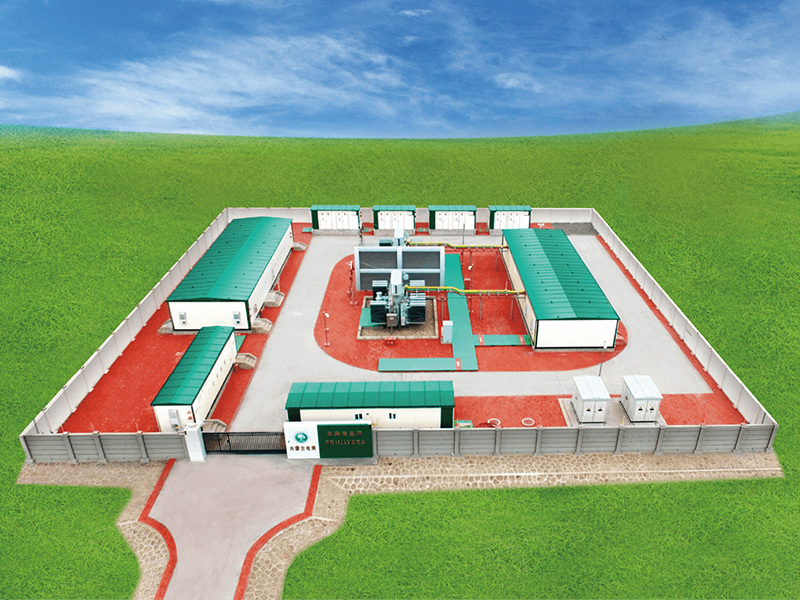

The company has nine professional production workshops including enclosure, electroplating, insulation, painting, processing, mechanism, assembly workshop one, assembly workshop two, and assembly workshop three. It is equipped with 33 high-precision horizontal and vertical machining centers from Germany DMG Mori, Japan Yamazaki Mazak, South Korea Hyundai WIA, South Korea Doosan, Taiwan Leadwell, as well as international advanced equipment and domestic equipment such as the Heinrich epoxy resin casting production line from Germany and the FMT longitudinal seam automatic welding machine from the United States, totaling more than 1200 sets, and helping the company’s process equipment reach the international advanced level. We’ve achieved a self-sufficiency rate of products over 95%, with an annual production capacity of 4,000 sets of combined apparatus and 3,600 circuit breakers.

The company has built a 1,100kV purification assembly workshop through continuous technological transformation, and equipped itself with high-voltage test and inspection equipment such as a 1,500kV test transformer. The enterprise management adopts advanced MIS information system with CAD and CAM widely adopted for product design and manufacturing, making the product structure layout more appropriate and scientific. Advanced technical processes, sophisticated tooling equipment, and perfect quality management can provide high-quality “Taikai” brand products for users in the power industry.